3M 471 Vinyl Tape Floor & Safety Marking Tape Alternatives

Augus vinyl tape is a replacement for 3M Vinyl Tape 471, is a conformable colored (9 colors plus transparent) tape made from vinyl backing with rubber adhesive. It is ideal for many lane and safety markings, color coding, abrasion protection, masking, sealing, splicing and other general purpose applications.

Typical Physical Properties:

| Adhesive Type | Rubber |

| Backing Thickness (mm) | 0.1 mm |

| Total Tape Thickness (mil) | 5.2 mil |

| Total Tape Thickness (mm) | 0.14 mm |

| Backing Thickness | 4.1 mil |

| Tensile Strength | 24.5 N/cm; 224 oz/in |

| 180° Peel Adhesion | 2.8 N/cm; 26 oz/in |

| Elongation at Break (%) | 150 % |

| Long Term Temp °C | 77 °C (170 °F) |

| Minimum Long Term Temperature Resistance | 4 °C (40 °F) |

Product Features:

Pigmented backings maintain their vivid colors even when exposed to heavy abrasion.

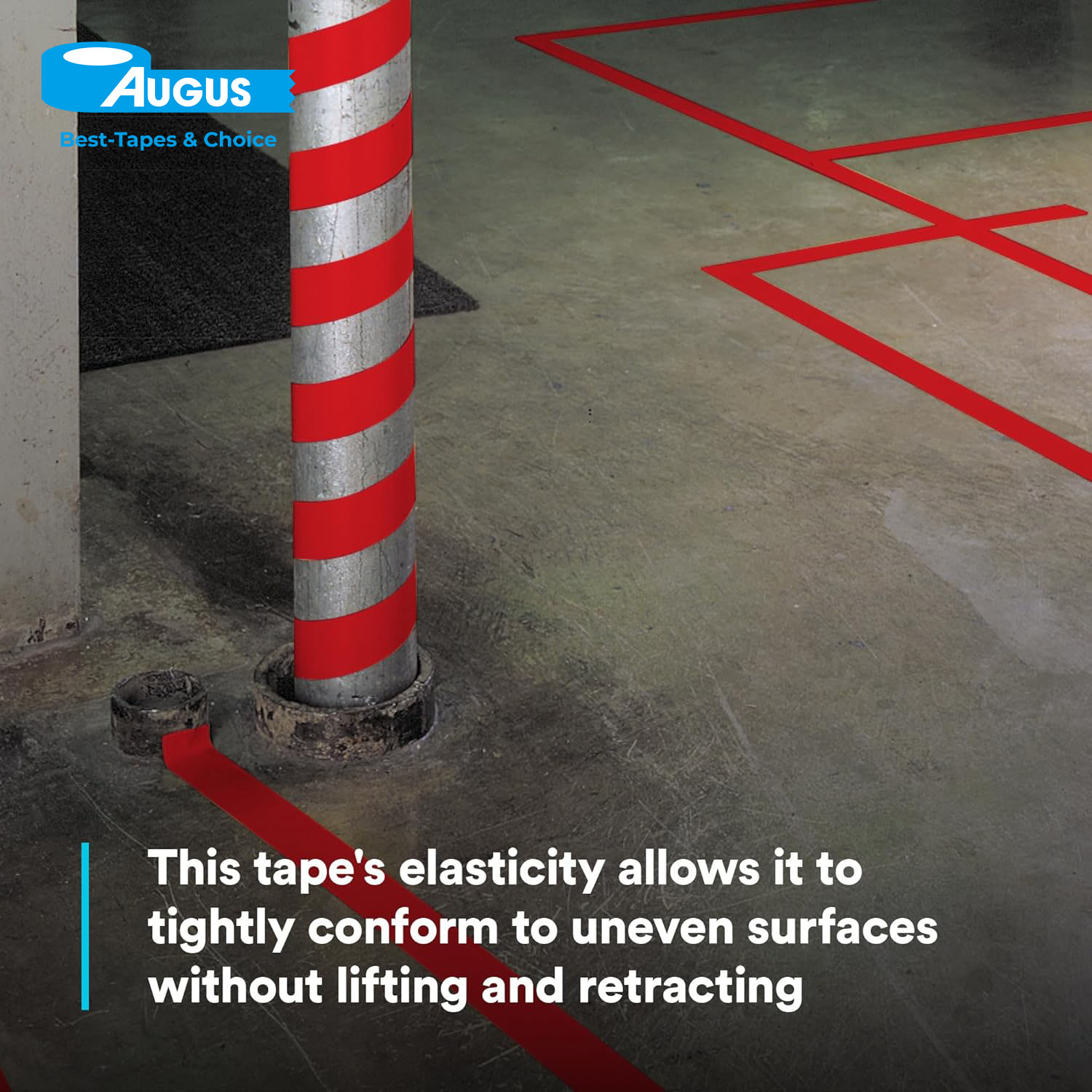

Conformability and dead stretch properties are ideal for taping, wrapping or sealing many curved, convex, or irregular surfaces.

Rubber adhesive provides good adhesion to many surfaces for easier application and excellent holding strength.

Sharp colors for color coding or marking systems, draw attention and help enhance plant safety.

Clean removal from many surfaces which helps reduce clean-up and labor costs.

Abrasion resistant and longer potential application life.

Good solvent resistance for application protection and longer product life.

Storage and Shelf Life:

Store under normal conditions of 60° to 80°F (16° to 27°C) and 40 to 60% R.H. in the original carton.

To obtain best performance, use this product within 18 months from date of manufacture.

Application Examples:

Excellent for many lane and safety marking applications. When used with an applicator like the M-77 dispenser, Vinyl Tape 471 can be quickly applied to define storage and safety areas.

Because it has low leachable halogens and sulfur, Vinyl Tapes 471 can be used in corrosion sensitive applications like the nuclear and stainless steel industries.

Augus tape 471 stretches to seal canisters and other storage containers that require a tight seal.

Vivid colors of the tapes make them ideal for color, coding and decorating.

Application Techniques:

Best results are attained when applied to a clean, dry surface at temperatures between 60° to 85°F (16° to 27°C).

Note: While tape 471 resists many common solvents, it should not be exposed to ketones, chlorinated hydrocarbons and esters found in lacquer thinner, degreasers, paint strippers, etc., which may cause the backing to swell or curl.

Note: The physical properties shown are tested by ASTM D1000 or our own procedures, it is recommended that the buyer determine the suitability for his own purposes.

Storage: Shelf life recommended one year from the date of dispatch at the moderate temperature and humidity environment.

Leave Your Message