3M 50# Vinyl Corrosion Protection Tape

Augus vinyl tape is a replacement for 3M Scotchrap 50, All-Weather Corrosion Protection Tape is used to protect metal piping systems against corrosion. Used for corrosion control.

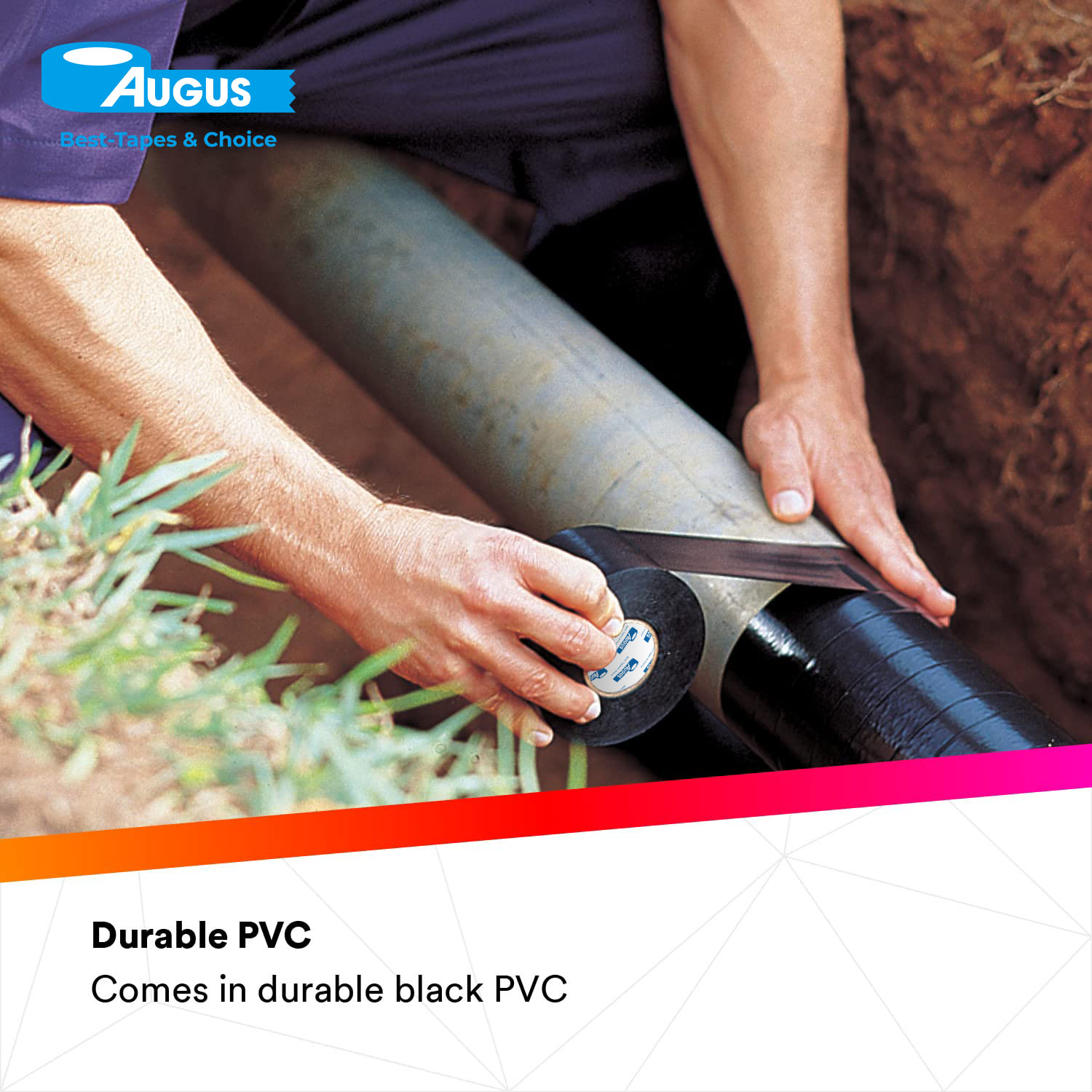

The tape works on metal piping systems above and below ground, fittings, and joints on all mill-coated pipe and electrical conduit systems.

Augus replacement for 3M Scotchrap 50 delivers excellent electrical and mechanical protection due to its elastic PVC backing combined with its pressure-sensitive rubber resin adhesive.

It is flame-retardant and is highly resistant to soil acids, chemical vapors, moisture, corrosive saltwater, alkalies, salts, common chemicals, and exposure to outdoor weathering and sunlight. This is also resistant to impact, abrasions, punctures, and tears. Traits include high conformability, all-weather, and works over a wide temperature range.

| Product Name | Vinyl Corrosion Protection Tape 50 |

| Product Description | 10 mil (0.254 mm) thick PVC backing with rubber pressure-sensitive adhesive, designed for corrosion protection of metal pipeline systems. Resistant to UV, salt spray, acids and alkalis, with a service temperature range of -48°C to 80°C |

| Backing/Adhesive | PVC backing, black rubber adhesive |

| Physical Properties | Elongation at break: 200% (23°C), 100% (-12°C); Tensile strength at break: 3.5 kN/m; Adhesion to steel: 0.22 kN/m (23°C), 0.33 kN/m (-12°C) |

| Electrical Properties | Dielectric breakdown voltage: 12 kV; Water absorption rate: 0.30% |

| Application Temperature | Application: -12°C to 65.6°C; Service: -48°C to 80°C |

| Shelf Life | 5 years (when stored at 10°C - 27°C with relative humidity < 75%) |

| Compliance | RoHS 2011/65/EU, UL Listed, VDE 0340-TEIL1 |

CORROSION RESISTANT: Helps protect metal piping systems from corrosion

OPTIMIZED ADHERENCE: Provides excellent tacking with pressure-sensitive, rubber adhesive

DURABLE PVC: Comes in durable black PVC

EASY TO APPLY: No special tools are required for application

Note: The physical properties shown are tested by ASTM D1000 or our own procedures, it is recommended that the buyer determine the suitability for his own purposes.

Storage: Shelf life recommended one year from the date of dispatch at the moderate temperature and humidity environment.

Leave Your Message